Research

Multiscale Interfacial Dynamics for Materials Design and Performance Prediction

Multiscale Interfacial Dynamics for Materials Design and Performance Prediction

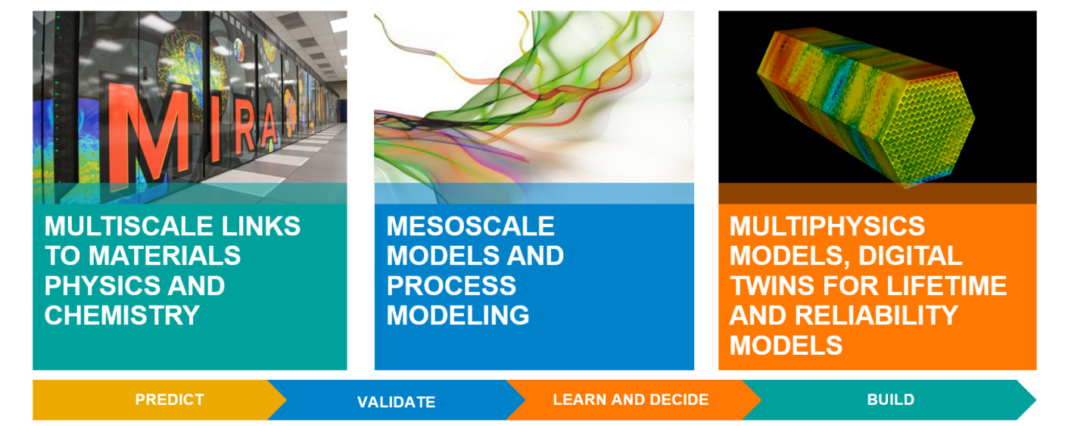

The expanding complexity of material composition, morphology, and processing methods is making mesoscale material science increasingly complex. Current state-of-the-art atomistic theories need to continuously grow to keep up with the pace of modern-day materials science. I plan to focus my group’s effort on establishing the missing connection between phase transformations, transport, and reaction dynamics in mesoscale. For mesoscale evolution of new phases in a compositions space, it is important to know the accessible stable/metastable phases possible for a certain pressure/temperature condition. This data is absent in standard materials databases. Therefore, the first thrust area of theory development is about the high-throughput screening of the potential energy landscape of phases and phase transformation mechanisms powered by machine learning methods and physics-based simulations. The second thrust in the group is building exascale-ready computational tools in coupled multi-resolution mesoscale models for thermal-and-mass transport, phase nucleation, growth, and phase transitions under different thermo-chemo-mechanical conditions. Finally, multiscale theory cannot be a standalone part of building understanding without the integration of experimental data, sensors, and AI-based tools. The new part of our activities which integrated academic groups, national laboratories (ORNL and ANL), and NIST involves the integration of AI to reduce the time needed to predict outcomes using a purely physics-based approach. The third thrust in my research group is the use of AI for multiscale control of experiments for discovery and scale-up of advanced materials. Our latest work developing a manufacturing data and machine learning (MDML) platform can integrate experimental and simulated data in an AI-based platform. Ongoing work in autonomous steering of experiments, optimization of processes, and use of streaming data analytics on a low-latency framework are being tested by collaborators in Argonne National Laboratory. The NASEM committee on the future of manufacturing and chemical engineering invite me to present our approach for AI for Multiscale Control of Complex and Uncertain Process Environment and their report will highlight this as a frontier for engineering in the next decade.

Research Outline

Design of Coatings and Fluids using Atomistic Simulations

Molecular dynamics for anti-icing coatings; Fluids for tribological applications; Adhesive performance and debonding mechanisms; Simulations of anti-corrosion smart coatings and additives

Chemistry under Extreme Conditions

First-principles kinetics of gas-phase and condensed-phase reactions; Transition state theory and RRKM Rate Constants; Reactive molecular dynamics; Coarse-graining of reactive simulations; Shock and Shear Flow in Solid and Liquids using MD Simulations; Atomistic-to-continuum connection in reactive flow

Electrochemical Reactions

DFT calculation of surface chemical pathways under anodic and cathodic conditions; MD simulation of transport near electrode surface; Multiphysics model of electrochemical process; Dissolution and passivation of oxide layers in implantable sensors

Evolutionary Search of Phase diagram and Crystal Structures

High-throughput DFT screening of formation enthalpy and electronic structure; Compounds and crystal structure search; Comparing results with Materials Genome databases; Hierarchical theoretical methods for uncertainty quantification

Materials for Energy Storage and Conversion

Hydrogen storage systems and catalytic cycles; DFT screening of phases; Nanoscale evolution of surface alloys and dealloying dynamics;

MADE-PUBLIC - Future of Printed Electronics

Building Materials Research using Multiscale Science Approach

- Professor Santanu Chaudhuri leads M3L at UIC. Dr. Chaudhuri directed the the development of Manufacturing Science and Engineering program for energy materials at the Argonne National Lab and was part of the Argonne leadership team.

- University of Illinois at Urbana-Champaign: Moved to the University of Illinois at Urbana-Champaign in 2014 where he served as the Associate Director of the Applied Research Institute (ARI) at UIUC. His research group (Multiscale Materials and Manufacturing Lab) worked on applications of high-performance computing in energy, environment and manufacturing applications for improving the efficiency of materials insertion and deployment.

- Washington State University: Joined Washington State University’s Department of Physics and Astronomy, and led the development of Applied Sciences Laboratory.

- Brookhaven National Laboratory: Worked from 2003–2006 at Brookhaven National Laboratory’s Center for Functional Nanomaterials on a theory-guided design of hydrogen storage materials for automobile applications.

- NATO Scholarship: Received NATO scholarship to work at Oxford University developing simulation methods for ionic conductors, catalysts, and battery materials.

- Education: Ph.D. in Materials Chemistry and Chemical Physics from SUNY Stony Brook in 2003.