We are on UIC News TODAY! Heading link

The race for capturing carbon hinges on finding needles in a haystack, and trial and error is too slow. You have billions and billions of possibilities, and then you must narrow down to candidates that are good carbon absorbers,” said Santanu Chaudhuri, professor of civil, materials and environmental engineering at UIC and director of manufacturing science and engineering at Argonne. “With this project, we have taken the first significant step towards closing that gap by using generative AI.

Research Focus Heading link

-

Mesoscale and Multiphysics Modeling

Connection of atomic scale averages to the mesoscale using coarse-grained, discrete element, fluid dynamics, and finite element models; multiphysics models of materials processing and manufacturing.

-

First-Principles and Molecular Dynamics Simulations

Density functional theory (DFT) for solids, alloys, and compounds; classical, reactive, and coarse-grain molecular dynamics of materials.

-

Data and Machine Learning

High-throughput DFT databases, automation of simulations and learning from molecular dynamics, machine learning for the acceleration of first-principles thermodynamic calculations, machine learning for materials property predictions, reinforcement learning for steering of experiments and manufacturing processes.

-

High-performance Computing

Integration of edge-to-exascale computing and machine learning acceleration hardware in advanced materials design, scale-up, and manufacturing.

M3L Heading link

Data-enabled Discovery of Materials

Develop an ability to steer searches compounds, alloys, and metastable states with unique properties using genetic algorithms for generations of crystal structure guesses with progressively better structural motif or stability.

- A search of alloys and compounds in the phase diagram

- Materials for a circular economy

- Design of corrosion-resistant microstructure

- Nanostructured coatings

- Design of molecular and hybrid crystals

- Additive-manufacturing

- 3D printing of electronics and sensors

- Bio-based and bio-sourced materials such as bioplastics

Creating high performance materials

As articulated in a recent DOE report “The ability to predict and control mesoscale phenomena and architectures is essential if atomic and molecular knowledge is to blossom into the next generation of technology opportunities, societal benefits, and scientific advances”. The challenge of modeling phenomena in the mesoscale is scaling the system size and the physics to the boundaries of nano-and-microscale where continuum behaviors emerge. Due to recent advances in precision in 3D printing, mesoscale assembly of materials through proper control of transport, reactions, and phase segregation processes are possible. However, there remain large gaps in understanding mesoscale. The outcome of the research at M3L is an ability to predict Structure-Property-Performance-and-Processing (SPPP) correlations in complex mesoscale architectures under dynamic thermo-chemo-mechanical conditions and bridge fundamental science constructs to the engineering scale.

Selected Publications in 2023 Heading link

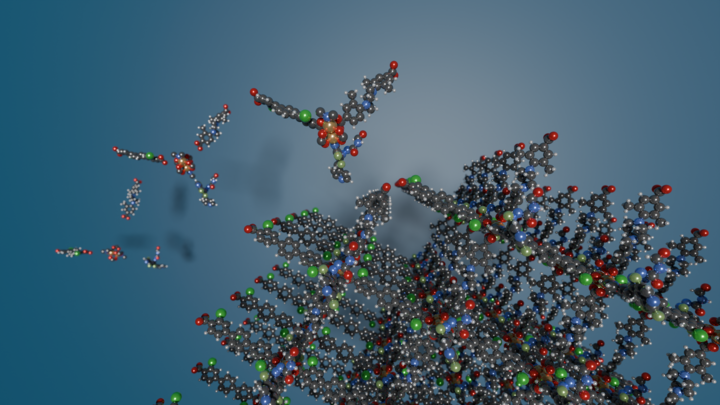

Hyun Park, Xiaoli Yan, Ruijie Zhu, Eliu A Huerta, Santanu Chaudhuri, Donny Cooper, Ian Foster, Emad Tajkhorshid: A generative artificial intelligence framework based on a molecular diffusion model for the design of metal-organic frameworks for carbon capture.

https://www.nature.com/articles/s42004-023-01090-2